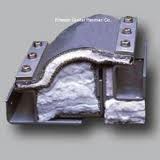

GTX Gas Turbine Fabric Expansion Joints are available in a variety of steel frame designs and fabric expansion joint materials. All standard fabric expansion joint designs can be modified to suit most customer requirements.

The new revolutionary fabric expansion joint design solutions introduced with the GTX-range of fabric expansion joints that have been achieved through several years of testing, involving intensive use of FEA-calculations (Finite Element Analysis). There are three standard fabric expansion joint designs available:

GTX-A: This fabric expansion joint is used in applications that have no pressure pulses and have fairly smooth flow velocities. The fabric expansion joint design is typically used on units installed down stream of the gas turbine, after the diffuser sections where the gas flow characteristics have smoothed.

GTX-B: This is the most commonly used fabric expansion joint design that will withstand normal pressure pulses and flow conditions. A unit composed of this fabric expansion joint design can be installed e.g. at the bypass outlet sections or after the diffuser sections.

GTX-C: This fabric expansion joint design is recommended for heavy-duty gas turbine exhaust applications where high pressure pulsations with turbulent flow conditions exist.

Based on the information provided by our customer, the choice of bellows type is generally suggested by SIlverfox.